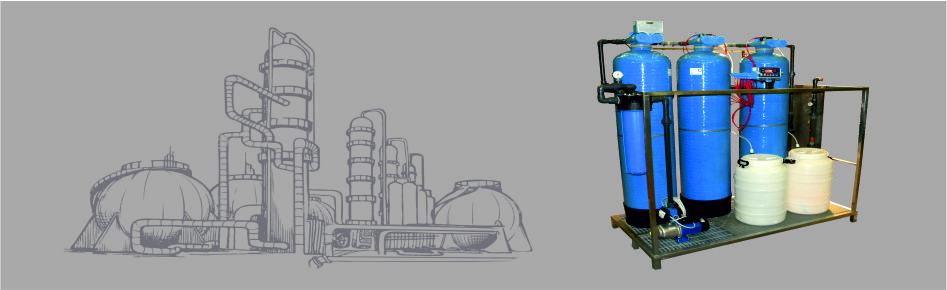

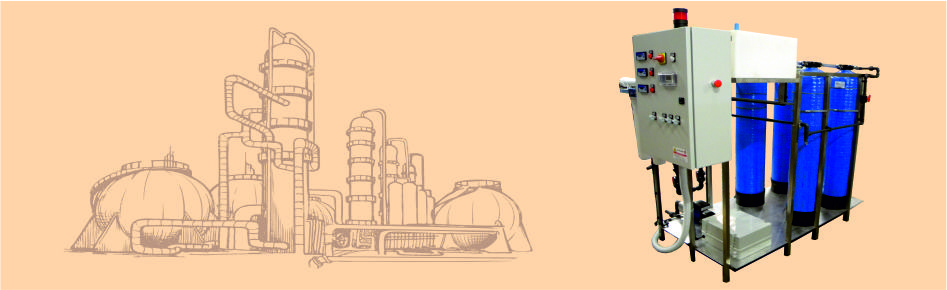

RO 4000-8000-12000 EL-TS demineralizer for industrial uses

|

Applications

|

BASE VERSION |

BiOs VERSION - Pharmaceutical industry - Galvanic industry - Rinse raw product in general - Rinse glassware and optical lenses - Preparation industrial reagents - Industrial uses preparation of process water |

BiOs-EDI VERSION - Electronic Industry - Fine galvanic industria - Production chemical reagents for laboratory - Medical industry - Industrial uses prep. water of process - As indicated for version BiOs |

| quality standard | quality standard | quality standard |

|

purified water (Di normally |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. Conduct. 25°C: 0.2-3 mcS/cm El. Spec. Resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. Conduct. 25°C: 0.1-1 mcS/cm El. Spec. Resisit. 25°C: 10 MOhm.cm |

Quality and technology at the service of industries

The demineralizer RO 4000-8000-12000 is designed to produce deionized water of high purity for industrial technical uses. The high technology applied and the excellent quality of the components guarantee reliability and durability.

Three versions to suit every need.

RO 4000-8000-12000 is produced in three versions to meet every need of pure water in modern industry:

BASE VERSION - Produced water with single shift to Reverse Osmosis. The quality of the membranes used ensures a maximum reduction of 99%, a project with average recovery of 40-50%. The water produced may be defined PURIFIED WATER.

BiOs VERSION - Produced water with double shift to Reverse Osmosis (Bi osmosis). After the first pass the water is stored in a tank where it performs a series of instrumental controls, to then be sent automatically to the second passage. This system guarantees a maximum reduction of 99.5% with an average recovery of 40-45%. The water produced is usually complies with the requirements of European Pharmacopoeia (EU).

El. Spec. conductivity. typical: 0.8-4.2 microS/cm

BiOs-EDI VERSION - Produced water with proceedings Bi osmosis and further purification with cEDI system. cEDI (Continuous electrodeionization) is an innovative system which consists in passing the water through ion exchange resins, while a controlled electric current operates a continuous regeneration of the resins themselves, so that these do not undergo a progressive depletion with the need to periodic replacement. The result is demineralized water with high degree of purity and extremely low operating costs. In reference to the common standards of purity, the water produced can be judged to conform to ISO 3696 grade 2.

El. Spec. resistivity at 25 ° C - 10-18 MOhm.cm

Automation and control

All versions of RO 4000-8000-12000 are equipped with an electronic control unit to the PLC interfaced with the PC (in TS models is also present a TOUCH SCREEN panel), that manages all the operating steps and functional checks and in particular:

- Manual operation

- Manual operation

- Automatic operation

- Filling of a storage tank with 2 level sensors (min and max)

- Fill up the volume (through an integrated flow meter – optional)

- Control of the ON-line water quality by means of digital instruments

- Quality of produced water (standard on all models)

- Water Quality first stage (standard on BIOS and BIOS versions EDI)

- PH water first stage (standard on BIOS-EDI version)

- Feed water quality (optional)

- Control of the operational flows

- Integrated Magnetics gauges in the control PLC (standard on BIOS-EDI version)

- Mechanical direct reading flowmeters (standard on BASIC and BIOS versions)

- Check the pressure

- Check the pressure

- Low-pressure feed water with automatic block for lack of water

- Maximum operating pressure with automatic lock

(std on BiOS and BiOS versions EDI)

- Feed water pressure transducer with analog (std on BIOS-EDI version)

- Operating pressures analog transducer (std on BIOS-EDI version)

- Feed water and operating pressure with mechanical gauges

(Standard on BASIC and BIOS versions).

- General alarm integrated into the PLC

- red flashing light and dedicated message on the display PLC or TS

- Feed water quality (optional)

TECHNICAL FEATURES |

|||||

RO 4000 |

RO 8000 |

RO 10000 |

RO 12000 |

||

| - operative pressure RO elements - DAILY PRODUCTION - MIN. feed pressure - MAX. feed pressure - temp. of water to be treated - HOURLY PRODUCTION - hidraulic connections

|

|

bar 8-12 mc 40-50 bar 2,5 bar 4,5 °C 5-35 lt/h 4000 2" V ac 380 |

bar 8-12 mc 80-100 bar 2,5 bar 4,5 °C 5-35 lt/h 8000 2" V ac 380 |

bar 8-12 mc 100-120 bar 2,5 bar 4,5 °C 5-35 lt/h 10000 2"1/2 V ac 380 |

bar 8-12 mc 120-150 bar 2,5 bar 4,5 °C 5-35 lt/h 12000 2"1/2 V ac 380 |

| DIMENSIONS | |||

| BASE VERSION | BiOs VERSION | BiOs EDI VERSION | |

| Lenght max | cm 160 | cm 320 | cm 320 |

| Width max | cm 87 | cm 120 | cm 120 |

| Heifht max | cm 140 | cm 140 | cm 140 |

| TECHNICAL SPECIFICATION OF WATER FEED | |

| max permissible values | |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 1000 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

2 - Storage tank in PE HD internal or external. with anti-dust system, whose water level is regulated by N°2 magnetic sensors, a maximum (block) and a minimum (restart production). Third sensor can be installed to indicate a level below the minimum due to il being accidental implantation.

3 - sensor of a minimum pruduction interfaced with the PLC, warning the user, through an appropriate alarm message on the machine, that the apparatus is producing at a rate lower than the minimum allowable. Possibility remoting.

print RO for industrial uses