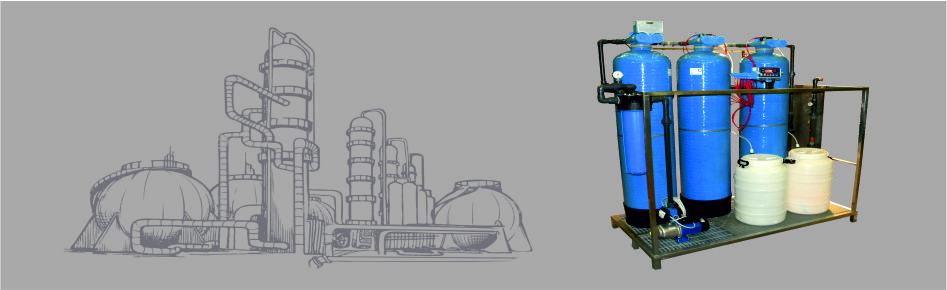

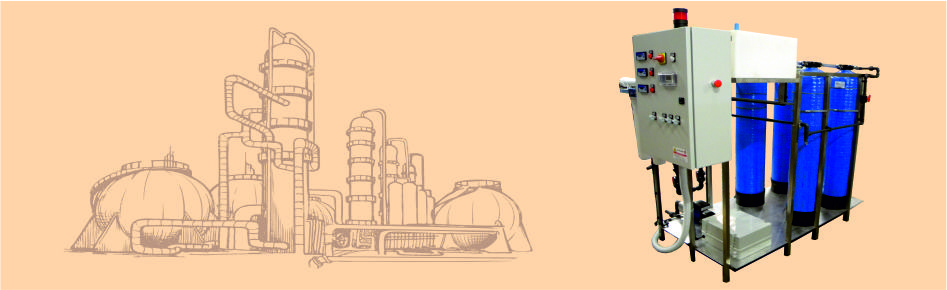

OSMO FEED - reverse osmosis purificator for technical uses

|

OSMO FEED is a water purifying and de-mineralising system destined specifically for technical use. It is able to produce de-mineralised water using the reverse osmosis method, obtaining a desalination level greater than 90% and a specific conductivity at 25°C not greater than 30 microS/cm.

The solution to power equipment with water purified

OSMO FEED is designed and built to produce desalinated water for industrial use, while maintaining ease of operation and maintenance, and reduced plant needs for its operation. OSMO FEED is used in all applications where there is need for water with low salinity level and at the same time under pressure. You can also connect multiple tanks to increase its total capacity, type of build-up bottles with tap water to fall to the bottom ( capacity lt 25-50-100), or take water from pressurized circuit including special taps a button (one of which supplied standard). The routine maintenance provide regular scheduled replacement cartridges sediment pre-filter and filter activated carbon (or sediment pre-filter 2). The water produced can be considered of good quality not just from the salt but also from an organic (average 97/98%).

Easy to deploy and install, easy to use

Due to small size, can be easily accommodated in the immediate vicinity of a sink and connected without the aid of special hydraulic engineering. The water produced is stored in a pressurized tank of capacity of 12 or 19 lt; the blockade and opening the flow are fully automated. OSMO FEED also does not need electricity because it works with the pressure of the network and does not require special hydraulic works for its installation. For best results of treatment have enough water coming acquedottistica or otherwise having the characteristics described in the technical specifications. Transactions of use and maintenance were also provided for non-specialist personnel practices being particularly simple and quick.

Accessories

- Storage tank lt 25, 50, 100, 200 PE HD

- Pressure storage tank lt 19 additional

- Group 20" - Filters + Chartridges

- UV sterilizer

- Reverse osmosis module for parallel installation (port.6-8 lt/h)

| TECHNICAL FEATURES | APPLICATION | |||

| - HOURLY PRODUCTION | lt/h | 4-5 | - Feeding of glass items washers | |

| - DAILY PRODUCTION | lt | 80-90 | - Feeding of surge tanks, general-purpose boilers | |

| - min. feed pressure | bar | 2,5 | - Feeding of thermostatic baths | |

| - max feed pressure | bar | 4,5 | - Feeding of ultra-pure water systems | |

| - temp. water to be treated | °C | 5-35 | - Feeding autoclaves, boilers in general | |

| - hidraulic connection | IN | pipePE 6 | ||

| OUT | pipePE 6 | |||

| DRAIN | pipePE 6 | |||

| DIMENSIONS | FEED WATER REQUIREMENT | ||||

|

max permessible values | ||||

| Purificator | TDS | ppm 500 | |||

| Lenght | cm 35 | Total Hardness | °F 30 | ||

| Width | cm 18 | Iron | ppb 100 | ||

| Height | cm 40 | Manganese | ppb 5 | ||

| Tank | Chlor | ppm 0,1 | |||

| Diametrer | cm 27 | SDI | < 5 | ||

| Altezza | cm 42 | Total bacteria | < 5 UFC/ml | ||

print OSMO FEED