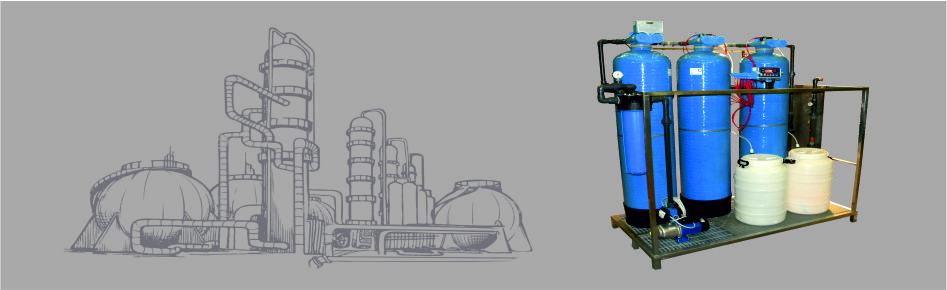

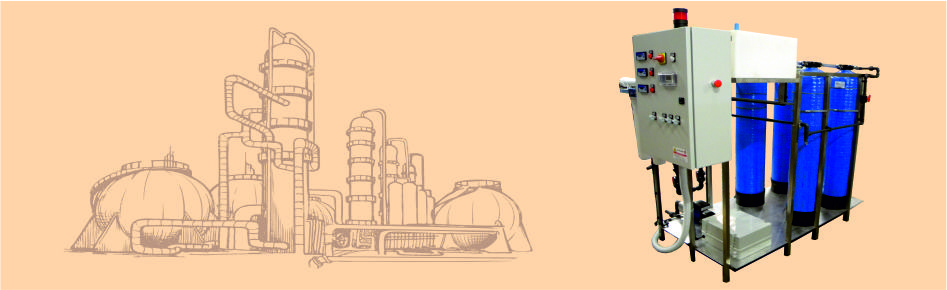

UPW refiner fr - apparatus for the production of ultra-pure water grade1 - Supplied directly of aqueduct

| QUALITY STANDARD | DIMENSIONS | |||

| ISO 3696 | grade 1 | Lenght | cm 44 | |

| ASTM | Type I | Width | cm 46 | |

| NCCLS | Type I | Height | cm 52 | |

| EP/USP | conform | |||

| SPEC. EL. RESISTIVITY at 25°C | 18,2 MOhm.cm | Dry Weight | kg 27 | |

A fully automated apparatus to produce ultra pure water of grade 1

UPW refiner fr is a water purification system for the production of ultra pure water up to an electrical resistivity spec.di 18.2 MOhm.cm, suitable for analytical applications of high precision.

Production of ultra pure water of grade 1 through 5 different types of purification

UPW refiner is feed by water from the waterwork (characteristics correspond to the parameters listed in Table 2). UPW refiner fr is able to produce fully purified water from the saline (Spec electrical resistivity at 25 ° C - 18.2 MOhm.cm) and levels are very low (<10 ppb), thanks to an automatically controlled recirculation and 5 different types of purification:

- Sediment filtration

- Purification with reverse osmosis

- Ion exchange resins type 1 and 2

- Photo oxidation with UV rays

- Microfiltration 0,2 micron antibacteria

Simplicity of operation and store of water always available

UPW refiner is very easy to use, since fully automatic in its duties and has a single button to levy placed on the front panel and provides a reservoir of water of 5 liters, which is restored after each use by the operator.

| Table 1 | |

| - Max production for each cycle - Accuracy resistivimeter - Max delivery dispenser - Min. pressure feed water - Temperature of the feed water - Electric power |

Lt/h 5 MOhm.cm 0,1 Lt/min 1 2,5 atm °C 5-35 V-AC 220 |

| Table 2 - Requirements of Water feed |

|

| - TDS max - Pressure min/max - Temperature min/max - HD max - Iron max - Manganese max - chlor max - Total Bacteria - SDI |

300 ppm 2,0-4,5 bar 5 - 35 °C 30 °F 100 ppb 5 ppb 0,1 ppm max 5 UFC/ml < 5 |

| Specifications Produced Water Quality |

|

| - Specific Resistivity water product - TOC - Total Bacteria - pH |

18 MOhm.cm < 15 ppb < 1 neutral at the production |

OPTIONAL ACCESSORIES

FLASH SAMPLING. The flask sampling for UPW refiner is designed to take samples which must not be exposed to the air: a system of ball valves and tubes leak, allow to completely fill the flask, and after the operation the sampling, isolate the sample from the outside until use. The operations of connection and release are in very practical due to the use of quick connectors. |

||

PRESSURE STORAGE TANK Lt 16 (net 8-9). PRESSURE STORAGE TANK Lt 16 (net 8-9).If you get there with Osmo Lab UPW or LAB OSMO 2 in order to reduce the load times and therefore increase the efficiency of purification, you should insert the feeding tube of the tank lt 16 in pressure to be provided as an accessory (code 0000244).

|

||

print UPW REFINER fr