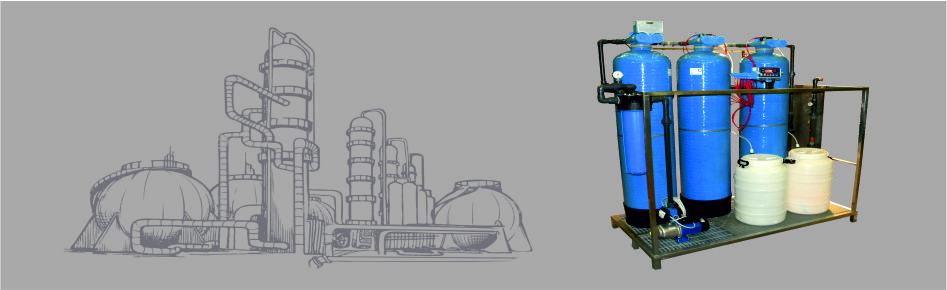

The iron removal systems DFTE-p, DFTE-h, and DFTE-b series are fully automatic systems whose filter bed is defined based on the overall characteristics of the water being treated. The materials that can be used as filter beds are:

DFTE-p

Pyrolusite. This is the common name for the natural mineral manganese dioxide. It is a mined mineral with a manganese dioxide content of 40-85% by weight. Pyrolusite treatment can achieve an iron removal rate of 20 mg/L or more.

Pyrolusite is an oxidizing material with a high specific gravity of approximately 4.0.

It can be used in two ways:

- Together with sand and anthracite, in varying percentages (QFTE Series), to combine the filtering power of sand with the oxidizing power of pyrolusite;

- Using 100% pyrolusite (DFTE series) in a suitable filter for oxidation and filtration.

No chemical regeneration is necessary. Backwashing, preferably with air injection, is necessary for proper filter operation.

DFTE-h

Hylox. This is a revolutionary and technologically advanced product, entirely manufactured in Europe. Its composition makes it exceptionally competitive with the most common filter products used for water treatment (sand, BIRM, Greensand Plus, manganese Greensand, etc.). HYLOX LIGHT® was designed with a unique MnO2 coating technique, which ensures lighter mass, greater filter surface area, longer life, and more reliable performance (filtration down to 3 μm) than any other existing filter media. HYLOX LIGHT® is ideal for numerous residential, commercial, industrial, and municipal systems designed for advanced filtration, the removal of color, odor, iron, manganese, hydrogen sulfide, and the reduction of arsenic, zinc, copper, lead, radium, uranium, and other radionuclides and heavy metals. HYLOX LIGHT® is certified for drinking water applications (ANSI/NSF 61) and complies with ANSI/NSF 372.

DFTE-b

Birm (Burgess Iron Removal Method). Birm is produced by activating manganese salts to saturation on aluminum silicate sand. The manganese ions are then oxidized to solid form with potassium permanganate. To ensure the oxidizing effect of the birm, the presence of dissolved oxygen (D.O.) in the water being treated is required, and the alkalinity should be greater than twice the combined concentration of sulfates and chlorides. Air insufflation may also be necessary to achieve a dissolved oxygen content that exceeds at least 15% of the iron content, especially if the water to be treated has an Fe concentration > 3.0 mg/L. Dissolved oxygen oxidizes the iron, while the BIRM acts as a catalyst that enhances the reaction between oxygen, iron, and dissolved manganese.

The BIRM cannot be used for water containing H2S or organic matter in concentrations > 4-5 mg/L. Chlorination significantly reduces the BIRM's efficiency and significantly lowers its catalytic properties.

No chemical dosage or regeneration is required for the BIRM to function properly.

The absolute non-toxicity and unique features of these iron removers make them one of the most widely used treatment techniques in Europe and the United States. Furthermore, thanks to the remarkable versatility of the pilot valves, it is possible to intervene on both the times and the flow rates of the backwashes in order to adapt each system to the specific water to be treated and to the user's needs.

Models

| MODEL | capacity | diameters I/O | electric power | dimensions |

| (lt) | (incs) | V-AC | cm | |

| DFTE 35 | 35 | 1 | 220-12 | 88(h)x25(d) |

| DFTE 55 | 55 | 1 | 220-12 | 165(h)x34(d) |

| DFTE 85 | 85 | 1 | 220-12 | 195(h)x35(d) |

| DFTE 110 | 100 | 1-1/2 | 220-12 | 195(h)x40(d) |

| DFTE 150 | 150 | 1-1/2 | 220-12 | 195(h)x50(d) |

| DFTE 250 | 250 | 1-1/2 | 220-12 | 195(h)x55(d) |

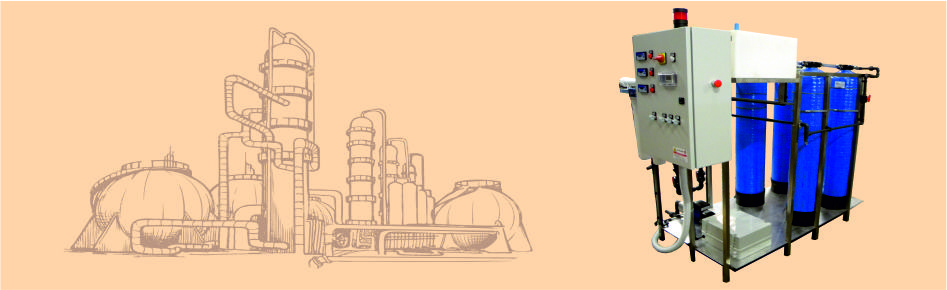

Models of INDUSTRIAL series

This series of filters is specifically designed for plant engineering, depending on the precise needs of use and quality of the water to be treated.

The containers used are of the type with a perforated plate in carbon steel Teflon coated internally and enamelled externally with polyurethane varnish.

The pilot valves are of the hydraulic membrane type with inclined seat, pneumatic control, 2 ways.

In the case of duplex or modular realizations in general, the connection pipes between the elements are made of TIG-welded stainless steel; the flow opening and closing valves used are of the butterfly type sandwich between flanges.

The general control panel, built according to the safety regulations in force, uses a PLC, capable of managing the service and washing phases and is interfaced with a touch screen keypad, for real-time display of the system's operating status.

As a rule, these designs include INOX sock filters both in input (sand protection) and outgoing (as safety).

print FILTER TO REMOVE IRON AND MANGANESE