Models

|

OSMO FEED is a water purifying and de-mineralising system destined specifically for technical use. It is able to produce de-mineralised water using the reverse osmosis method, obtaining a desalination level greater than 90% and a specific conductivity at 25°C not greater than 30 microS/cm.

The solution to power equipment with water purified

OSMO FEED is designed and built to produce desalinated water for industrial use, while maintaining ease of operation and maintenance, and reduced plant needs for its operation. OSMO FEED is used in all applications where there is need for water with low salinity level and at the same time under pressure. You can also connect multiple tanks to increase its total capacity, type of build-up bottles with tap water to fall to the bottom ( capacity lt 25-50-100), or take water from pressurized circuit including special taps a button (one of which supplied standard). The routine maintenance provide regular scheduled replacement cartridges sediment pre-filter and filter activated carbon (or sediment pre-filter 2). The water produced can be considered of good quality not just from the salt but also from an organic (average 97/98%).

Easy to deploy and install, easy to use

Due to small size, can be easily accommodated in the immediate vicinity of a sink and connected without the aid of special hydraulic engineering. The water produced is stored in a pressurized tank of capacity of 12 or 19 lt; the blockade and opening the flow are fully automated. OSMO FEED also does not need electricity because it works with the pressure of the network and does not require special hydraulic works for its installation. For best results of treatment have enough water coming acquedottistica or otherwise having the characteristics described in the technical specifications. Transactions of use and maintenance were also provided for non-specialist personnel practices being particularly simple and quick.

Accessories

- Storage tank lt 25, 50, 100, 200 PE HD

- Pressure storage tank lt 19 additional

- Group 20" - Filters + Chartridges

- UV sterilizer

- Reverse osmosis module for parallel installation (port.6-8 lt/h)

| TECHNICAL FEATURES | APPLICATION | |||

| - HOURLY PRODUCTION | lt/h | 4-5 | - Feeding of glass items washers | |

| - DAILY PRODUCTION | lt | 80-90 | - Feeding of surge tanks, general-purpose boilers | |

| - min. feed pressure | bar | 2,5 | - Feeding of thermostatic baths | |

| - max feed pressure | bar | 4,5 | - Feeding of ultra-pure water systems | |

| - temp. water to be treated | °C | 5-35 | - Feeding autoclaves, boilers in general | |

| - hidraulic connection | IN | pipePE 6 | ||

| OUT | pipePE 6 | |||

| DRAIN | pipePE 6 | |||

| DIMENSIONS | FEED WATER REQUIREMENT | ||||

|

max permessible values | ||||

| Purificator | TDS | ppm 500 | |||

| Lenght | cm 35 | Total Hardness | °F 30 | ||

| Width | cm 18 | Iron | ppb 100 | ||

| Height | cm 40 | Manganese | ppb 5 | ||

| Tank | Chlor | ppm 0,1 | |||

| Diametrer | cm 27 | SDI | < 5 | ||

| Altezza | cm 42 | Total bacteria | < 5 UFC/ml | ||

print OSMO FEED

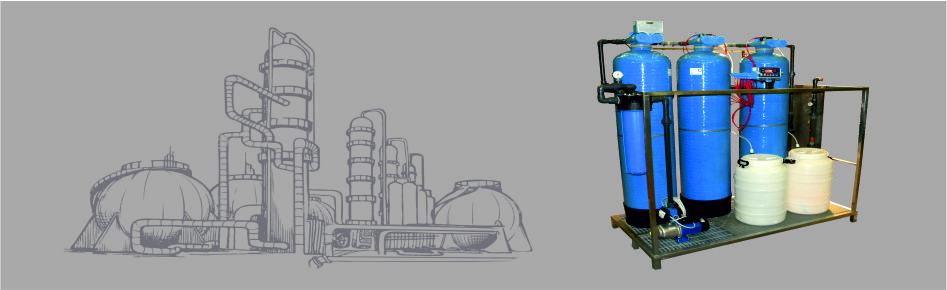

A different model for each user's needs

.

2 models

- RO 15 CUBIC-S2 15 lt/h

- RO 30 CUBIC-S2 30 lt/h

3 PURITY GRADES

RO CUBIC-S2 base - purified water produced only with reverse osmosis process

| REFERENCE STANDARD | RO CUBIC-S2/d | RO CUBIC-S2/d2 |

| ISO 3696 | grade 3 | grade 2 |

| ASTM | Type III | Type II |

| NCCLS | Type III | Type II |

| EP/USP | conform (W/filtro 0,2m) | conform |

EL. SPEC. CONDUCIBILITY AT 25°C (d) 0.2-3 MicroS/cm - EL. SPEC.RESISTIVITY AT 25°C (d2) 10-18,2 MOhm.cm

4 stages of purification

- sediment micro-filter

- reverse osmosis whit booster pump

- mixed bed resins whit different purity grade for different quality water product

- anti bacteria micr-filter 0,2 micron (opzional for model /d2)

4 operating modes

- manual ON/OFF

- automatic ON/OFF whit 2 sensor levels for storage tank (min/max)

- manual ON and automatic OFF (whit sensor level for storage tank)

- manual ON and OFF whit flow-meter (opzional and volume preset)

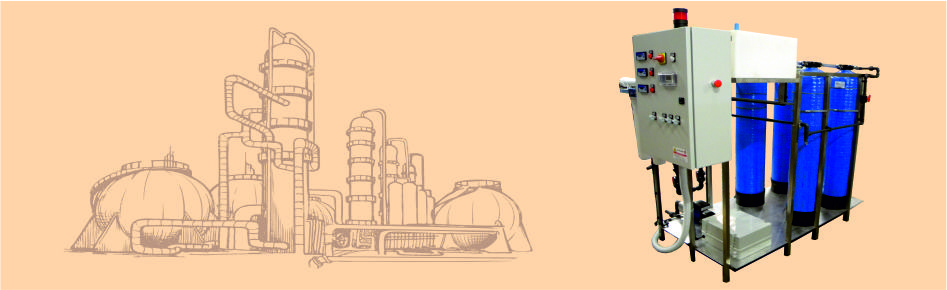

A simple and efficient control panel

The RO CUBIC-S2 line is equipped with an efficient control panel in the front and easily viewable by the operator.

- 2 manometers (pressure feed water, operating pressure), steel case and glycerine

- Digital conductivity meter for monitoring the quality of water supplied; wide LCD diplay, possibility to remote the measured value with the output 4-20 mA configurable

- PLC control unit with LCD display

- Cumulative fault warning light (low pressure, replacement pre filter, water quality, replacing anti bacterial filter when present

Applications

- HPLC (d2)

- Spettrofotometric analisys atomic absortion (d2)

- Preparations/diluitions reagents (d-d2)

- Qualitative colorimetric analysis (d)

- feed ultra-pure water systems, boilers, etc. (base-d)

- feed glassware washer (base-d)

- feed steam generators (base-d)

- feed ultrasonic systems, thermostatic baths (base-d)

| TECHNICHAL FEATURES | FEED WATER REQUIREMENTS | |||

| - min. feed pressure | bar 2,5 | - TDS | max 500 ppm | |

| - max. feed pressure | bar 4,0 | - HD | max 30 °F | |

| - max. operative pressure | bar 8,0 | - Iron | max 100 ppb | |

| - temp. of water to be treated | °C 5-35 | - Manganese | max 5 ppb | |

| - hidraulic connection | IN pipe PE 8 | - Chlor | max 0,1 ppm | |

| OUTpipe PE 6 | - total Bacteria | max 5 UFC/ml | ||

| DRAIN pipe PE 6 | - SDI | < 5 | ||

| - alimentazione elettrica | V 220 ac | |||

| ACCESSORIES | DIMENSIONS | |||

| Storage tank PE-HD | lt. 25, 50, 100, 200 | Lenght | 65 cm | |

| BOOSTER PUMP for pressure line water product | Width | 37 cm | ||

| Debatterrizzatore a raggi UV | Height | 60 cm | ||

| Anti bacteria filter 0,2 micron | ||||

| Flow meter integrated in PLC | Weight max | 30 kg | ||

NEWS!!!!

ACCESSORY FOR FINISHING THE SALINE CONTENT

(water produced for trace analysis)

The increasing demand in laboratories for the analysis of demineralised water with a high degree of purity, both from a chemical and organic point of view, has made it necessary to create a specific accessory for finishing the salt content, until the state of ultrapure water is reached, suitable for trace chemical analysis.

This appliance which can be installed at the exit of demineralizers of the RO CUBIC S2 line in the d2 version which already guarantees a degree of purity of the water produced equal to 2 according to ISO 3696.

After the passage on the 3 columns of resin put in series, the water quality is monitored by means of a digital resistivity meter with reading in MOhm.com and subsequently filtered on a 0.2 micron cartridge with antibacterial screen function, as well as for the removal of any traces of metal oxides left in suspension.

After the treatment described above, the water supplied may have a specific electrical resistivity up to 18.2 MOhm.com.

1 mg / lt = 1 ppm = 1000 ppb it is also specified that it is not possible to make certain predictions on the concentration of each individual

electrolyte, in the case it is necessary to subject the drawn water to production to a competent chemical analysis.

print RO CUBIC S2 base

print RO CUBIC S2 d & d2

|

Applications

|

BASE VERSION |

BiOs VERSION - Pharmaceutical industry - Galvanic industry - Rinse raw product in general - Rinse glassware and optical lenses - Preparation industrial reagents - Industrial uses preparation of process water |

BiOs-EDI VERSION - Electronic Industry - Fine galvanic industria - Production chemical reagents for laboratory - Medical industry - Industrial uses prep. water of process - As indicated for version BiOs |

| quality standard | quality standard | quality standard |

|

purified water (Di normally |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. Conduct. 25°C: 0.2-3 mcS/cm El. Spec. Resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. Conduct. 25°C: 0.1-1 mcS/cm El. Spec. Resisit. 25°C: 10 MOhm.cm |

Quality and technology at the service of industries

The demineralizer RO 750 is designed to produce deionized water of high purity for industrial technical uses. The high technology applied and the excellent quality of the components guarantee reliability and durability.

Three versions to suit every need.

RO 750 is produced in three versions to meet every need of pure water in modern industry:

BASE VERSION - Produced water with single shift to Reverse Osmosis. The quality of the membranes used ensures a maximum reduction of 99%, a project with average recovery of 40-50%. The water produced may be defined PURIFIED WATER.

BiOs VERSION - Produced water with double shift to Reverse Osmosis (Bi osmosis). After the first pass the water is stored in a tank where it performs a series of instrumental controls, to then be sent automatically to the second passage. This system guarantees a maximum reduction of 99.5% with an average recovery of 40-45%. The water produced is usually complies with the requirements of European Pharmacopoeia (EU).

El. Spec. conductivity. typical: 0.8-4.2 microS/cm

BiOs-EDI VERSION - Produced water with proceedings Bi osmosis and further purification with cEDI system. cEDI (Continuous electrodeionization) is an innovative system which consists in passing the water through ion exchange resins, while a controlled electric current operates a continuous regeneration of the resins themselves, so that these do not undergo a progressive depletion with the need to periodic replacement. The result is demineralized water with high degree of purity and extremely low operating costs. In reference to the common standards of purity, the water produced can be judged to conform to ISO 3696 grade 2.

El. Spec. resistivity at 25 ° C - 10-18 MOhm.cm

Automation and control

All versions of RO 750 are equipped with an electronic control unit to the PLC interfaced with the PC (in TS models is also present a TOUCH SCREEN panel), that manages all the operating steps and functional checks and in particular:

- Manual operation

- Manual operation

- Automatic operation

- Filling of a storage tank with 2 level sensors (min and max)

- Fill up the volume (through an integrated flow meter – optional)

- Control of the ON-line water quality by means of digital instruments

- Quality of produced water (standard on all models)

- Water Quality first stage (standard on BIOS and BIOS versions EDI)

- PH water first stage (standard on BIOS-EDI version)

- Feed water quality (optional)

- Control of the operational flows

- Integrated Magnetics gauges in the control PLC (standard on BIOS-EDI version)

- Mechanical direct reading flowmeters (standard on BASIC and BIOS versions)

- Check the pressure

- Check the pressure

- Low-pressure feed water with automatic block for lack of water

- Maximum operating pressure with automatic lock

(std on BiOS and BiOS versions EDI)

- Feed water pressure transducer with analog (std on BIOS-EDI version)

- Operating pressures analog transducer (std on BIOS-EDI version)

- Feed water and operating pressure with mechanical gauges

(Standard on BASIC and BIOS versions).

- General alarm integrated into the PLC

- red flashing light and dedicated message on the display PLC or TS

- Feed water quality (optional)

| TECHNICAL FEATURES | |

| - DAILY PRODUCTION | lt 7500-8500 |

| - HOURLY PRODUCTION | lt/h 720 |

| - feed pressure min./max. | bar 2,5/4,5 |

| - temperature of water to be treated | °C 5-35 |

| - operative pressure RO elements | bar 9-11 |

| - hidraulic connection | IN: pipe 1"1/2 |

| OUT: pipe PE 1/2" | |

| DRAIN: pipe 1/2" | |

| - ELECTRIC POWER | V 380 AC |

| DIMENSIONS | |||

| BASE VERSION | BiOs VERSION | BiOs EDI VERSION | |

| Lenght max | cm 160 | cm 320 | cm 320 |

| Width max | cm 87 | cm 120 | cm 120 |

| Heifht max | cm 140 | cm 140 | cm 140 |

| TECHNICAL SPECIFICATION OF WATER FEED | |

| max permissible values | |

| - TDS | ppm 500 |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 1000 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

2 - Storage tank in PE HD internal or external. with anti-dust system, whose water level is regulated by N°2 magnetic sensors, a maximum (block) and a minimum (restart production). Third sensor can be installed to indicate a level below the minimum due to il being accidental implantation.

3 - sensor of a minimum pruduction interfaced with the PLC, warning the user, through an appropriate alarm message on the machine, that the apparatus is producing at a rate lower than the minimum allowable. Possibility remoting.

print RO 750 EL-TS

|

Applications

|

BASE VERSION |

BiOs VERSION - Pharmaceutical industry - Galvanic industry - Rinse raw product in general - Rinse glassware and optical lenses - Preparation industrial reagents - Industrial uses preparation of process water |

BiOs-EDI VERSION - Electronic Industry - Fine galvanic industria - Production chemical reagents for laboratory - Medical industry - Industrial uses prep. water of process - As indicated for version BiOs |

| quality standard | quality standard | quality standard |

|

purified water (Di normally |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. Conduct. 25°C: 0.2-3 mcS/cm El. Spec. Resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. Conduct. 25°C: 0.1-1 mcS/cm El. Spec. Resisit. 25°C: 10 MOhm.cm |

Quality and technology at the service of industries

The demineralizer RO 400 is designed to produce deionized water of high purity for industrial technical uses. The high technology applied and the excellent quality of the components guarantee reliability and durability.

Three versions to suit every need.

RO 400 is produced in three versions to meet every need of pure water in modern industry:

BASE VERSION - Produced water with single shift to Reverse Osmosis. The quality of the membranes used ensures a maximum reduction of 99%, a project with average recovery of 40-50%. The water produced may be defined PURIFIED WATER.

BiOs VERSION - Produced water with double shift to Reverse Osmosis (Bi osmosis). After the first pass the water is stored in a tank where it performs a series of instrumental controls, to then be sent automatically to the second passage. This system guarantees a maximum reduction of 99.5% with an average recovery of 40-45%. The water produced is usually complies with the requirements of European Pharmacopoeia (EU).

El. Spec. conductivity. typical: 0.8-4.2 microS/cm

BiOs-EDI VERSION - Produced water with proceedings Bi osmosis and further purification with cEDI system. cEDI (Continuous electrodeionization) is an innovative system which consists in passing the water through ion exchange resins, while a controlled electric current operates a continuous regeneration of the resins themselves, so that these do not undergo a progressive depletion with the need to periodic replacement. The result is demineralized water with high degree of purity and extremely low operating costs. In reference to the common standards of purity, the water produced can be judged to conform to ISO 3696 grade 2.

El. Spec. resistivity at 25 ° C - 10-18 MOhm.cm

Automation and control

All versions of RO 400 are equipped with an electronic control unit to the PLC interfaced with the PC (in TS models is also present a TOUCH SCREEN panel), that manages all the operating steps and functional checks and in particular:

- Manual operation

- Manual operation

- Automatic operation

- Filling of a storage tank with 2 level sensors (min and max)

- Fill up the volume (through an integrated flow meter – optional)

- Control of the ON-line water quality by means of digital instruments

- Quality of produced water (standard on all models)

- Water Quality first stage (standard on BIOS and BIOS versions EDI)

- PH water first stage (standard on BIOS-EDI version)

- Feed water quality (optional)

- Control of the operational flows

- Integrated Magnetics gauges in the control PLC (standard on BIOS-EDI version)

- Mechanical direct reading flowmeters (standard on BASIC and BIOS versions)

- Check the pressure

- Check the pressure

- Low-pressure feed water with automatic block for lack of water

- Maximum operating pressure with automatic lock

(std on BiOS and BiOS versions EDI)

- Feed water pressure transducer with analog (std on BIOS-EDI version)

- Operating pressures analog transducer (std on BIOS-EDI version)

- Feed water and operating pressure with mechanical gauges

(Standard on BASIC and BIOS versions).

- General alarm integrated into the PLC

- red flashing light and dedicated message on the display PLC or TS

- Feed water quality (optional)

| TECHNICAL FEATURES | |

| - DAILY PRODUCTION | lt 4000-5000 |

| - HOURLY PRODUCTION | lt/h 400 |

| - feed pressure min./max. | bar 2,5/4,5 |

| - temperature of water to be treated | °C 5-35 |

| - operative pressure RO elements | bar 7-9 |

| - hidraulic connection | IN: pipe 1"1/2 |

| OUT: pipe PE 1/2" | |

| DRAIN: pipe 1/2" | |

| - ELECTRIC POWER | V 220-380 AC |

| DIMENSIONS | |||

| BASE VERSION | BiOs VERSION | BiOs EDI VERSION | |

| Lenght max | cm 95 | cm 250 | cm 250 |

| Width max | cm 83 | cm 120 | cm 120 |

| Heifht max | cm 130 | cm 140 | cm 140 |

| TECHNICAL SPECIFICATION OF WATER FEED | |

| max permissible values | |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 500 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

2 - Storage tank in PE HD internal or external. with anti-dust system, whose water level is regulated by N°2 magnetic sensors, a maximum (block) and a minimum (restart production). Third sensor can be installed to indicate a level below the minimum due to il being accidental implantation.

3 - sensor of a minimum pruduction interfaced with the PLC, warning the user, through an appropriate alarm message on the machine, that the apparatus is producing at a rate lower than the minimum allowable. Possibility remoting.

print RO 400 EL-TS

|

Applications

|

BASE VERSION |

BiOs VERSION - Pharmaceutical industry - Galvanic industry - Rinse raw product in general - Rinse glassware and optical lenses - Preparation industrial reagents - Industrial uses preparation of process water |

BiOs-EDI VERSION - Electronic Industry - Fine galvanic industria - Production chemical reagents for laboratory - Medical industry - Industrial uses prep. water of process - As indicated for version BiOs |

| quality standard | quality standard | quality standard |

|

purified water (Di normally |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. Conduct. 25°C: 0.2-3 mcS/cm El. Spec. Resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. Conduct. 25°C: 0.1-1 mcS/cm El. Spec. Resisit. 25°C: 10 MOhm.cm |

Quality and technology at the service of industries

The demineralizer RO 1000 is designed to produce deionized water of high purity for industrial technical uses. The high technology applied and the excellent quality of the components guarantee reliability and durability.

Three versions to suit every need.

RO 1000 is produced in three versions to meet every need of pure water in modern industry:

BASE VERSION - Produced water with single shift to Reverse Osmosis. The quality of the membranes used ensures a maximum reduction of 99%, a project with average recovery of 40-50%. The water produced may be defined PURIFIED WATER.

BiOs VERSION - Produced water with double shift to Reverse Osmosis (Bi osmosis). After the first pass the water is stored in a tank where it performs a series of instrumental controls, to then be sent automatically to the second passage. This system guarantees a maximum reduction of 99.5% with an average recovery of 40-45%. The water produced is usually complies with the requirements of European Pharmacopoeia (EU).

El. Spec. conductivity. typical: 0.8-4.2 microS/cm

BiOs-EDI VERSION - Produced water with proceedings Bi osmosis and further purification with cEDI system. cEDI (Continuous electrodeionization) is an innovative system which consists in passing the water through ion exchange resins, while a controlled electric current operates a continuous regeneration of the resins themselves, so that these do not undergo a progressive depletion with the need to periodic replacement. The result is demineralized water with high degree of purity and extremely low operating costs. In reference to the common standards of purity, the water produced can be judged to conform to ISO 3696 grade 2.

El. Spec. resistivity at 25 ° C - 10-18 MOhm.cm

Automation and control

All versions of RO 1000 are equipped with an electronic control unit to the PLC interfaced with the PC (in TS models is also present a TOUCH SCREEN panel), that manages all the operating steps and functional checks and in particular:

- Manual operation

- Manual operation

- Automatic operation

- Filling of a storage tank with 2 level sensors (min and max)

- Fill up the volume (through an integrated flow meter – optional)

- Control of the ON-line water quality by means of digital instruments

- Quality of produced water (standard on all models)

- Water Quality first stage (standard on BIOS and BIOS versions EDI)

- PH water first stage (standard on BIOS-EDI version)

- Feed water quality (optional)

- Control of the operational flows

- Integrated Magnetics gauges in the control PLC (standard on BIOS-EDI version)

- Mechanical direct reading flowmeters (standard on BASIC and BIOS versions)

- Check the pressure

- Check the pressure

- Low-pressure feed water with automatic block for lack of water

- Maximum operating pressure with automatic lock

(std on BiOS and BiOS versions EDI)

- Feed water pressure transducer with analog (std on BIOS-EDI version)

- Operating pressures analog transducer (std on BIOS-EDI version)

- Feed water and operating pressure with mechanical gauges

(Standard on BASIC and BIOS versions).

- General alarm integrated into the PLC

- red flashing light and dedicated message on the display PLC or TS

- Feed water quality (optional)

| TECHNICAL FEATURES | |

| - DAILY PRODUCTION | lt 10000-12000 |

| - HOURLY PRODUCTION | lt/h 1000 |

| - feed pressure min./max. | bar 2,5/4,5 |

| - temperature of water to be treated | °C 5-35 |

| - operative pressure RO elements | bar 9-11 |

| - hidraulic connection | IN: pipe 1"1/2 |

| OUT: pipe PE 1/2" | |

| DRAIN: pipe 3/4" | |

| - ELECTRIC POWER | V 380 AC |

| DIMENSIONS | |||

| BASE VERSION | BiOs VERSION | BiOs EDI VERSION | |

| Lenght max | cm 160 | cm 320 | cm 320 |

| Width max | cm 87 | cm 120 | cm 120 |

| Heifht max | cm 140 | cm 140 | cm 140 |

| TECHNICAL SPECIFICATION OF WATER FEED | |

| max permissible values | |

| - TDS | ppm 500 |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 1000 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

2 - Storage tank in PE HD internal or external. with anti-dust system, whose water level is regulated by N°2 magnetic sensors, a maximum (block) and a minimum (restart production). Third sensor can be installed to indicate a level below the minimum due to il being accidental implantation.

3 - sensor of a minimum pruduction interfaced with the PLC, warning the user, through an appropriate alarm message on the machine, that the apparatus is producing at a rate lower than the minimum allowable. Possibility remoting.

print RO 1000 EL-TS