Models

| QUALITY STANDARD | FEED WATER REQUIREMENTS | |||

| ISO 3696 | grade 3 | - TDS max | 300 ppm | |

| ASTM | Type III | - HD max | 30 °F | |

| NCCLS (c/filtro 0,2 mcr) | Type III | - Iron max | 100 ppb | |

| EP/USP(c/filtro 0,2 mcr) | conf. | - Manganese max | 5 ppb | |

| - Chlor max | 0,1 ppm | |||

| SPEC. EL. CONDUCIBILITY at 25°C |

- total Bacteria max | 5 UFC/ml | ||

|

0,2-3 microS/cm |

- SDI | < 5 | ||

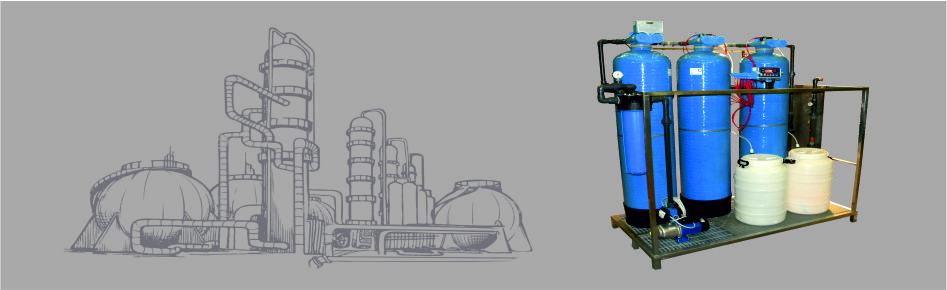

A simple and versatile instrument indispensable in the laboratory

OSMO LAB 2 is a demineralizers able to produce pure water of Grade 3, suitable for all general purpose of a laboratory analysis. Its simplicity of operation and its versatility makes it an extremely reliable and therefore indispensable.

OSMO LAB 2 can be powered directly from the water network and its functioning exploits the pressure.

The water produced is stored in a tank in PE lt 25 (standard), but can also be equipped with a pressure system with 2 dispenser from which you can take is to use purified water accessories, water pure Grade 3 . The two types of tanks can be connected simultaneously.

Careful use of space

In modern laboratories the spaces available are increasingly reduced, so OSMO LAB 2 can be easily accommodated even in places not very accessible (inside furniture, wall hanging, local secondary). The user will have available on a work bench or more tanks, one or more reservoirs in PE HD with capacities from 25 to 100 lt; one or more storage tanks under pressure, with a reserve of 9-10 liters of water and 2 dispenser , the operation of the still fully automatic.

4 purification stages

> microfilter anti sediments

> reverse osmosis

> Ion excange resins, mixed bed

> microfiltrer 0,2 micron anti bacteria (optional and only applicable to pressure tank with dispenser)

| TECHNICAL FEATURES | APPLICATIONS | ||

| - DAILY PRODUCTION | Lt 80-90 | - General laboratory uses | |

| - min/max. feed pressure | bar 2,5-4,5 | - Glass works rinsing | |

| - feeed water temperature | °C 5-35 | - Preparation / diluting of reagents | |

| - HOURLY PRODUCTION | lt/h 3-4 | - Colorimetric and qualitative analyses | |

| - Hydraulic connection | IN rilsan 6/4 | - Feeding of thermostatic baths | |

| OUT rilsan 6/4 | - Feeding of glass works washers |

||

| DRAIN rilsan 6/4 | |||

| - ELECTRIC POWER | V 220 ac/12 ac | ||

print OSMO LAB2

| APPLICATIONS | QUALITY STANDARD | ||

| Spectro-photometric analysis in atomic absorption | ISO 3696 | grade 2 | |

| Reagents preparation/dilution | ASTM | Type II | |

| Colorimetric and qualitative analysis | NCCLS (w/antibacteria final filter) | Type II | |

| Feeding of ultra-pure water systems, surge tanks, etc. | EP/USP(w/antibacteria final filter) | conf. | |

| Feeding of glass works washers | |||

| Feeding of steam generators | SPEC. EL. RESISTIVITY AT 25°C | ||

| HPLC Cromatography | 10-18,2 MOhm.cm | ||

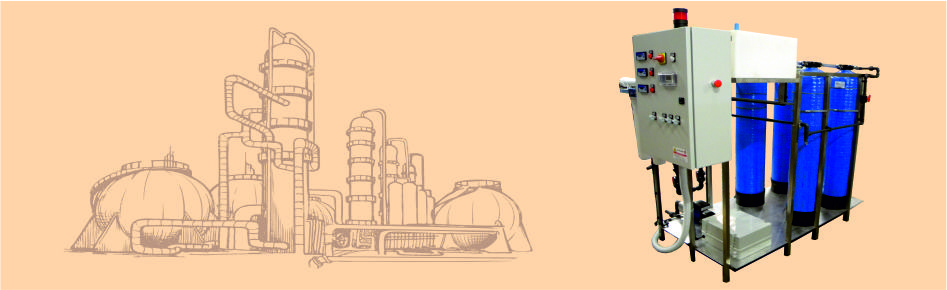

A complete system of water purification indispensable in any laboratory

Thanks to the possibility of delivering two types of water at the same time, OSMO LAB UPW 3 is an increasingly indispensable tool for most needs in small and medium-sized analysis laboratories.

Careful use of space

In modern laboratories the spaces available are increasingly reduced; for this reason OSMO LAB UPW 3 can be easily housed in places that are not very accessible (inside furniture, hanging on the wall, ancillary rooms). The user will have the pressurized accumulation tank available on the workbench, with a water reserve of 8-9 liters net, on which there are 2 dispensers for the differentiated withdrawal of purified or pure grade II water. It is also possible to optionally connect 2 or more storage tanks even far from each other, OSMO LAB UPW 3 will manage them automatically anyway.

High quality water with low production costs

OSMO LAB UPW 3 is able to produce demineralized water with a degree of purity much higher than the minimum standards required for GRADE II, while maintaining very low production costs: in fact, OSMO LAB UPW 3 is fed directly from the aqueduct network without normally special pre-treatments; the purified water for auxiliary laboratory uses is produced only with the reverse osmosis method (without consumable materials for demineralization), while the pure GRADE II water is obtained with 2 different types of resins with a high degree of purity that allow high performance demineralization from the beginning to the end of their cycle.

The quality of the water produced is monitored using a digital conductivity meter, with a visual alarm of both purified and demineralized water with alarms that indicate the need to replace the ion exchange resins or the membrane.

2 TYPES OF WATER STILL AVAILABLE:

> purified water for technical uses

> pure water GRADE II (conf. ISO 3696)

4 STAGES OF PURIFICATION

> sediment microfiter

> reverse osmosis

> pure resin 1 and ultra pure resin 2

> anti bacteria microfilter 47 mm (opzional)

DIGITAL MONITORING OF PRODUCED WATER

> Conductivity water produced

> Alarm for change resins and membrane RO

| TECHNICAL FEATURES | FEED WATER REQUIREMENTS | |||

| - DAILY PRODUCTION | until 100 lt demi | - TDS max | 300 ppm | |

| until 200 lt purified | - HD max | 30 °F | ||

| - min. feed pressure | bar 2,0 | - Iron max | 100 ppb | |

| - max feed pressure | bar 4,0 | - Manganese max | 5 ppb | |

| - max operative pressure | bar 6,0 | - chlor max | 0,1 ppmax | |

| - feed water temperature | °C 5-35 | - Tot. Bacteria max | 5 UFC/ml | |

| - HOURLY PRODUCTION | lt/h 8-10 | - SDI | < 5 | |

| - ELECTRIC POWER | V 220 ac / 24 ac | |||

| - hydraulic connection IN/OUT/DRAIN | tubo PE 6/4 | |||

print OSMO LAB UPW 3

| QUALITY STANDARD | DIMENSIONS | |||

| ISO 3696 | grade 1 | Lenght | cm 44 | |

| ASTM | Type I | Width | cm 46 | |

| NCCLS | Type I | height | cm 52 | |

| EP/USP | conform | |||

| SPEC: EL: RESISTIVITY at 25°C | 18,2 MOhm.cm | dry Weight | kg 27 | |

| QUALITY STANDARD | DIMENSIONS | |||

| ISO 3696 | grade 1 | Lenght | cm 44 | |

| ASTM | Type I | Width | cm 46 | |

| NCCLS | Type I | Height | cm 52 | |

| EP/USP | conform | |||

| SPEC. EL. RESISTIVITY at 25°C | 18,2 MOhm.cm | Dry Weight | kg 27 | |

A fully automated apparatus to produce ultra pure water of grade 1

UPW refiner fr is a water purification system for the production of ultra pure water up to an electrical resistivity spec.di 18.2 MOhm.cm, suitable for analytical applications of high precision.

Production of ultra pure water of grade 1 through 5 different types of purification

UPW refiner is feed by water from the waterwork (characteristics correspond to the parameters listed in Table 2). UPW refiner fr is able to produce fully purified water from the saline (Spec electrical resistivity at 25 ° C - 18.2 MOhm.cm) and levels are very low (<10 ppb), thanks to an automatically controlled recirculation and 5 different types of purification:

- Sediment filtration

- Purification with reverse osmosis

- Ion exchange resins type 1 and 2

- Photo oxidation with UV rays

- Microfiltration 0,2 micron antibacteria

Simplicity of operation and store of water always available

UPW refiner is very easy to use, since fully automatic in its duties and has a single button to levy placed on the front panel and provides a reservoir of water of 5 liters, which is restored after each use by the operator.

| Table 1 | |

| - Max production for each cycle - Accuracy resistivimeter - Max delivery dispenser - Min. pressure feed water - Temperature of the feed water - Electric power |

Lt/h 5 MOhm.cm 0,1 Lt/min 1 2,5 atm °C 5-35 V-AC 220 |

| Table 2 - Requirements of Water feed |

|

| - TDS max - Pressure min/max - Temperature min/max - HD max - Iron max - Manganese max - chlor max - Total Bacteria - SDI |

300 ppm 2,0-4,5 bar 5 - 35 °C 30 °F 100 ppb 5 ppb 0,1 ppm max 5 UFC/ml < 5 |

| Specifications Produced Water Quality |

|

| - Specific Resistivity water product - TOC - Total Bacteria - pH |

18 MOhm.cm < 15 ppb < 1 neutral at the production |

OPTIONAL ACCESSORIES

FLASH SAMPLING. The flask sampling for UPW refiner is designed to take samples which must not be exposed to the air: a system of ball valves and tubes leak, allow to completely fill the flask, and after the operation the sampling, isolate the sample from the outside until use. The operations of connection and release are in very practical due to the use of quick connectors. |

||

PRESSURE STORAGE TANK Lt 16 (net 8-9). PRESSURE STORAGE TANK Lt 16 (net 8-9).If you get there with Osmo Lab UPW or LAB OSMO 2 in order to reduce the load times and therefore increase the efficiency of purification, you should insert the feeding tube of the tank lt 16 in pressure to be provided as an accessory (code 0000244).

|

||

print UPW REFINER fr