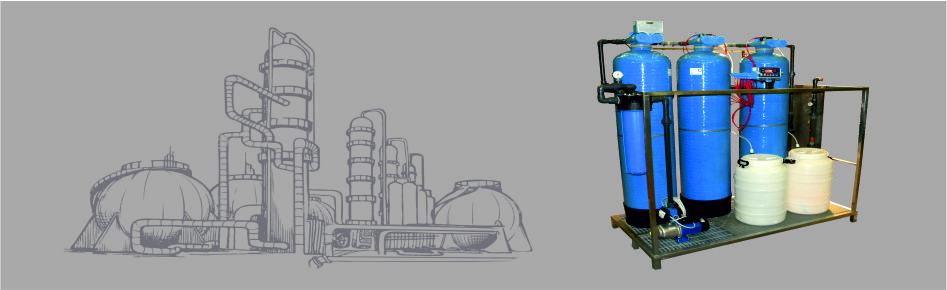

Models

|

Applications

| BASE VERSION Feeding of glass items washers Feeding of steam generators Feeding of thermostatic baths Feeding of ultra-pure water systems Autoclaves, boilers in general INDUSTRIAL USES |

demi VERSION Generalised laboratory uses Glass works rinsing Reagents preparation/dilution Colorimetric and qualitative analyses Feeding of thermostatic baths INDUSTRIAL USES |

demi2-TS VERSION HPLC chromatography Reagents preparation/dilution Colorimetric and qualitative analyses Spectro-phot. Analysis atomic absorption INDUSTRIAL USES As described for the DEMI version |

| quality standard | quality standard | quality standard |

|

purified water (usually El. Spec. Conductivity < 5-20 mcrS/cm) produced only with reverse osmosis system |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. conduct. 25°C: 0.2-3 mcrS/cm El. Spec. resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. conduct. 25°C: 0.1-1 mcrS/cm El. Spec. resist. 25°C: 10 MOhm.cm |

Quality, technology, versatility

OPERATIONAL CHARACTERISTICS OF THE ELECTRONIC CONTROL PANEL

start / stop manual, low pressure shutdown

A visual signal shows the various types of alarm: quality water with the consequent need to change resins (in demi and demi 2 versions) or exhaustion membranes (in the basic version); cartridge needs replacing pre-filter sediment or post-filter 0.2 microns if any.

| TECHNICAL FEATURES | DIMENSIONS | |||

| - DAILY PRODUCTION | lt 900-1200 | Lenght max | cm 53 | |

| - HOURLY PRODUCTION | lt/h 90 | Width max | cm 64 | |

| - Feed pressure | bar 2,5/4,5 | Height max | cm 137 | |

| - Temperature of water to be treated | °C 5-35 | |||

| - operative pressure RO elements | bar 14-15 |

|

||

| - hidraulic connection | IN: pipe 1/2" | |||

| OUT: pipe PE 10 | ||||

| DRAIN: pipe PE 10 | ||||

| - ELECTRIC POWER | V 220 AC | |||

| TECHINCAL SPECIFICATIONS WATER TO BE TREATED | |

| max permissible values | |

| - TDS | ppm 500 |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 500 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional Accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

print RO 90 EL-TS

|

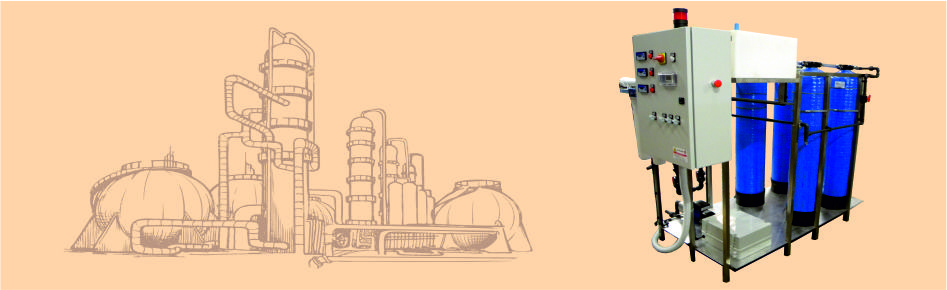

Applications

| BASE VERSION Feeding of glass items washers Feeding of steam generators Feeding of thermostatic baths Feeding of ultra-pure water systems Autoclaves, boilers in general INDUSTRIAL USES |

demi VERSION Generalised laboratory uses Glass works rinsing Reagents preparation/dilution Colorimetric and qualitative analyses Feeding of thermostatic baths INDUSTRIAL USES |

demi2-TS VERSION HPLC chromatography Reagents preparation/dilution Colorimetric and qualitative analyses Spectro-phot. Analysis atomic absorption INDUSTRIAL USES As described for the DEMI version |

| quality standard | quality standard | quality standard |

|

purified water (usually El. Spec. Conductivity < 5-20 mcrS/cm) produced only with reverse osmosis system |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. conduct. 25°C: 0.2-3 mcrS/cm El. Spec. resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. conduct. 25°C: 0.1-1 mcrS/cm El. Spec. resist. 25°C: 10 MOhm.cm |

Quality, technology, versatility

OPERATIONAL CHARACTERISTICS OF THE ELECTRONIC CONTROL PANEL

start / stop manual, low pressure shutdown

(optional) flushing system programmable membrane

A visual signal shows the various types of alarm: quality water with the consequent need to change resins (in demi and demi 2 versions) or exhaustion membranes (in the basic version); cartridge needs replacing pre-filter sediment or post-filter 0.2 microns if any.

| TECHNICAL FEATURES | DIMENSIONS | |||

| - DAILY PRODUCTION | lt 1600-2000 | Lenght max | cm 53 | |

| - HOURLY PRODUCTION | lt/h 160 | Width max | cm 64 | |

| - Feed pressure | bar 2,5/4,5 | Height max | cm 137 | |

| - Temperature of water to be treated | °C 5-35 | |||

| - operative pressure RO elements | bar 14-15 |

|

||

| - hidraulic connection | IN: pipe 1" | |||

| OUT: pipe PE 10 | ||||

| DRAIN: pipe PE 10 | ||||

| - ELECTRIC POWER | V 220 AC | |||

| TECHINCAL SPECIFICATIONS WATER TO BE TREATED | |

| max permissible values | |

| - TDS | ppm 500 |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 500 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional Accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

print RO 160 EL-TS

The DEMI FAST line has been studied for the production of demineralized water with high level of purity, for all those technical applications where moderate daily quantities are used (from 1 to a 200 lt/day) and it is required to have a suitable store available with really low costs of production.

APPLICATION FIELDS

- Supply-feeding sterilization apparatus

- Supply-feeding humidifiers

- Water mist fire extinguishers

- Refilling electrical accumulators

- Supply-feeding small steam boilers

- Printing press machines

MODELS

DEMI FAST mini

DEMI mini FAST is designed and constructed to produce demineralized water for all those applications where moderate amounts are used daily (1 to 50 lt / day) and you always want to have it available without bulky stock that normally will worsen the quality.

DEMI mini FAST is designed and constructed to produce demineralized water for all those applications where moderate amounts are used daily (1 to 50 lt / day) and you always want to have it available without bulky stock that normally will worsen the quality.

DEMI FAST mini comes with a special cartridge of ion exchange resins can remove all the minerals (salinity) contained in water, without releasing toxic or harmful to the users of application. Thanks to the simplicity and the high quality of materials used, DEMI FAST mini is extremely simple to use and less reliable in its operation. DEMI FAST mini produces continuously and can 'be used to feed all those devices that require a circuit of demineralized water under pressure.

|

The quality of the water produced is monitored continuously by a conductivity indicator to bar led, which indicates the time of DEMI FAST mini can also be fed with water of aqueduct, but for a higher yield and length of the cartridge is recommended osmotized |

TECHNICAL FEATURES - Hourly flow 30/40 lt/h - Dimensions Legth 19 cm |

DEMI FAST 10-20

DEMI FAST 10 and FAST 20 demineralizers are very advanced, designed for daily applications of water between 20 and 140 lt / day.

DEMI FAST 10 and FAST 20 demineralizers are very advanced, designed for daily applications of water between 20 and 140 lt / day.

Both models are equipped with 3 stages of purification:

- Sediment microfilter

- Reverse osmosis purifier

- Cartridge resin ion exchange mixed bed 1 micron

In this system the length of the cartridges is very high, so as to render the operating costs very low. The water produced is stored in a tank in PE from 50 liters with tap drawing on the base, the fill level is maintained automatically through an internal float.

In this system the length of the cartridges is very high, so as to render the operating costs very low. The water produced is stored in a tank in PE from 50 liters with tap drawing on the base, the fill level is maintained automatically through an internal float.

The quality of the water produced is monitored continuously by a conductivity indicator to bar led, which indicates the time of replacement cartridges.

TECHNICAL FEATURES

| DEMI FAST mini | DEMI FAST 10 | DEMI FAST 20 | |

Hourly production Daily production recomended El.Spec. conducibility water product medium life chartridge set Electric power Dimensions Lenght Width Height Storage tank |

30/40 lt/h 1-20 lt <5micrS/cm 140 lt 220 V AC -12V 19 cm 13 cm 66 cm |

3-5 lt/h 20-70 lt <5micrS/cm 500 lt 220 V AC-12V 37 cm 20 cm 39 cm Diam. 35 cm Height 70 cm |

6-10 lt/h 40-140 lt <5micrS/cm 1000 lt 220V AC-12V 37 cm 20 cm 70 cm Diam. 35 cm Height 70 cm |

| REQUIREMENTS OF WATER TO BE TREATED | ||

|

DEMI FAST mini |

DEMI FAST 10-20 | |

| - TDS | max 200 ppm | max 500 ppm |

| - HD | max 25 °F | max 30 °F |

| - iRON | max 50 ppb | max 100 ppb |

| - Manganese | max 5 ppb | max 5 ppb |

| - CHlor | max 0,1 ppm | max 0,1 ppm |

| - Total Bacteria | max 5 UFC/ml | max 5 UFC/ml |

| - SDI | / | < 5 |

print DEMI FAST

|

Applications

| BASE VERSION Feeding of glass items washers Feeding of steam generators Feeding of thermostatic baths Feeding of ultra-pure water systems Autoclaves, boilers in general INDUSTRIAL USES |

demi VERSION Generalised laboratory uses Glass works rinsing Reagents preparation/dilution Colorimetric and qualitative analyses Feeding of thermostatic baths INDUSTRIAL USES |

demi2-TS VERSION HPLC chromatography Reagents preparation/dilution Colorimetric and qualitative analyses Spectro-phot. Analysis atomic absorption INDUSTRIAL USES As described for the DEMI version |

| quality standard | quality standard | quality standard |

|

purified water (usually El. Spec. Conductivity < 5-20 mcrS/cm) produced only with reverse osmosis system |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. conduct. 25°C: 0.2-3 mcrS/cm El. Spec. resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. conduct. 25°C: 0.1-1 mcrS/cm El. Spec. resist. 25°C: 10 MOhm.cm |

Quality, technology, versatility

OPERATIONAL CHARACTERISTICS OF THE ELECTRONIC CONTROL PANEL

start / stop manual, low pressure shutdown

A visual signal shows the various types of alarm: quality water with the consequent need to change resins (in demi and demi 2 versions) or exhaustion membranes (in the basic version); cartridge needs replacing pre-filter sediment or post-filter 0.2 microns if any.

| TECHNICAL FEATURES | DIMENSIONS | |||

| - DAILY PRODUCTION | lt 2500-2800 | Lenght max | cm 65 | |

| - HOURLY PRODUCTION | lt/h 125 | Width max | cm 73 | |

| - Feed pressure | bar 2,5/4,5 | Height max | cm 137 | |

| - Temperature of water to be treated | °C 5-35 | |||

| - operative pressure RO elements | bar 14-15 |

|

||

| - hidraulic connection | IN: pipe 1" | |||

| OUT: pipe PE 10 | ||||

| DRAIN: pipe PE 10 | ||||

| - ELECTRIC POWER | V 220 or 380 AC | |||

| TECHINCAL SPECIFICATIONS WATER TO BE TREATED | |

| max permissible values | |

| - TDS | ppm 500 |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 500 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional Accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

3 - sensor of a minimum pruduction interfaced with the PLC, warning the user, through an appropriate alarm message on the machine, that the apparatus is producing at a rate lower than the minimum allowable. Possibility remoting.

print RO 250 EL-TS

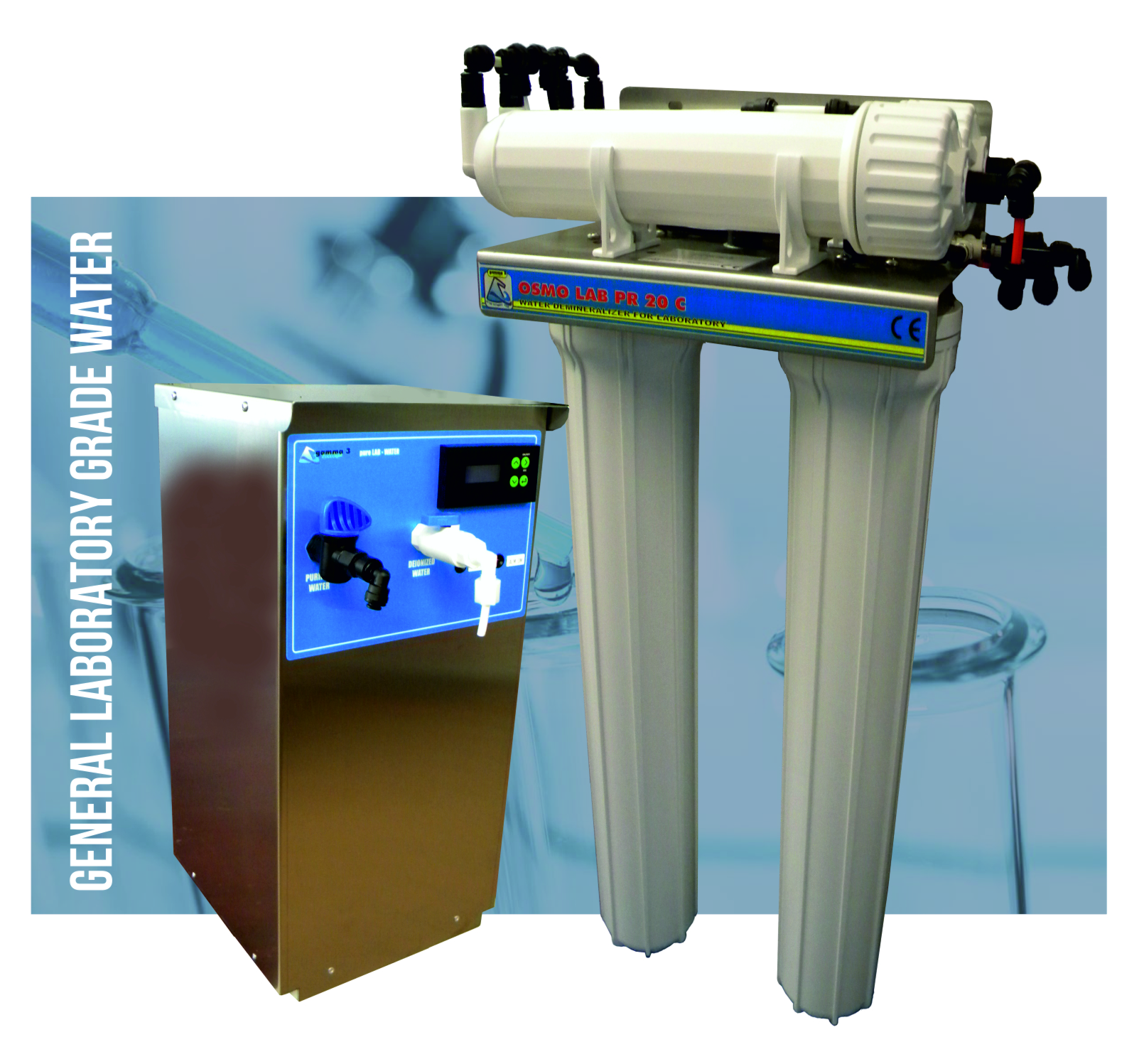

| QUALITY STANDARD | FEED WATER REQUIREMENTS | |||

| ISO 3696 | grade 3 | - TDS max | 300 ppm | |

| ASTM | Type III | - HD max | 30 °F | |

| NCCLS (w/filter 0,2 mcr) | Type III | - Iron max | 100 ppb | |

| EP/USP(w/filtrer 0,2 mcr) | conf. | - Manganese max | 5 ppb | |

| - chlor max | 0,1 ppm | |||

| SPEC. EL. CONDUCIBILITY at 25°C |

- Bacteria tot. max | 5 UFC/ml | ||

|

0,2-3 microS/cm |

- SDI | < 5 | ||

When you need to have more scope available

OSMO LAB pr 20 is designed to produce pure water grade 3 from tap water. OSMO LAB pr 20 has 2 osmosis membranes and therefore can guarantee a high production work with despite the pressure of 'waterworks. The size of the cartridge pre-filter and resin allows excellent autonomy before replacement.

Careful use of space

In modern laboratories the spaces available are increasingly reduced, so we thought OSMO LAB pr 20 so that it can be easily accommodated even in places not very accessible (inside furniture, wall hanging, local secondary). The user will have available on the bench working on tank pressure, with a reserve of 9-10 liters of water and on which there are 2 dispensers for the differential sampling of purified or pure grade 3. You can also optionally connect 2 or more storage tanks also distant among them, OSMO LAB pr 20 manage them automatically.

Water of good quality with low production costs

OSMO LAB pr 20 is able to produce demineralised water with purity usually above the minimum standards required for grade 3, however, keeping production costs low because OSMO LAB pr 20 is directly fed with water of wateworkr, without normally pre-treatment details; also uses purified water for laboratory assistant is produced only by a method for reverse osmosis (without material consumption for demineralization) and finally pure water GRADE 3 is obtained with resins of high purity, and these volumes to allow high-performance cycles of demineralization and higher production of 1000 liters per charge *. (*) The length of the cartridges of resin depends on the quality of feed water.

2 TYPES OF WATER STILL AVAILABLE:

- purified water for technical uses

- pure water GRADE 3 (conf. ISO 3696)

4 PURIFICATION STAGES

- sediment microfilter

- reverse osmosis

- mixed bed resins

- anti bacteria micro filter 47 mm (optional)

CONTINUOS MONITOR OF WATER PRODUCED

- El. conducibility purified water at 5 led

| TECHNICAL FEATURES | APPLICATIONS | ||

| - DAILY PRODUCTION | Lt 160-180 | - General laboratory uses | |

| - feed pressure min/max. | bar 2,5-4,5 | - Glass works rinsing | |

| - min/max temp. of feed water | °C 5-35 | - Preparation / diluting of reagents | |

| - HOURLY PRODUCTION | lt/h 6-8 | - Colorimetric and qualitative analyses | |

| - hydraulic connections | IN rilsan 6/4 | - Feeding of thermostatic baths | |

| OUT rilsan 6/4 | - Feeding of glass works washers | ||

| DRAIN rilsan 6/4 | |||

| - ELECTRIC POWER | V 220 ac/12 ac | ||

print OSMO LAB pr 20